In this episode of Innovations in Maritime, Marlon Grech, RightShip's Chief Product and Technology Officer, shares how RightShip builds AI-powered tools, hybrid inspections, and digital workflows to lead the next wave of maritime intelligence.

The maritime industry is shifting fast. As vessels, ports, cargo flows, and regulations grow more complex, the way we manage safety, sustainability, and operational risk must evolve with it.

In this episode of Innovations in Maritime, we sit down with Marlon Grech, RightShip’s Chief Product & Technology Officer, to explore how AI, data governance, and modern product design are redefining maritime intelligence.

From Agentic AI and workflow automation to hybrid inspections and the future of digital risk assessment, Marlon unpacks the technologies shaping how global maritime decisions will be made in the years ahead.

Q: You’ve had a front-row seat to transforming maritime risk through technology and AI. How does RightShip approach product discovery, and how do you decide what to build?

Marlon:

Our approach isn’t too different from the best product companies globally — it all starts with the voice of the customer. We anchor everything in the outcomes our customers need to achieve, and that drives our product strategy and roadmap.

Each item on the roadmap goes through a full product discovery process. We always begin with opportunity discovery, where our product team works side-by-side with real users to deeply understand the problem. In maritime, I often compare this to a root-cause analysis during a PSC or incident closeout — you can’t design the right solution unless you truly understand the underlying issue.

Once we’re confident we understand the problem, we move to solution discovery. Here we explore: How might we solve this? Will customers actually use a solution from RightShip? Would it meaningfully remove friction or add value? This stage is also validated directly with customers.

Only after that do we enter planning and development, where our engineering teams get together to figure out how to bring the solution to life. And finally, once something is launched, we enter evaluation — how is it being adopted? How is it being used? What patterns do we see?

It’s not a linear process. It’s an innovation loop. We release, test, get feedback, iterate, and cycle continuously. That’s what drives product innovation at RightShip.

Q: Risk management has historically been very manual and process-heavy. What gaps did you see in the status quo?

Marlon:

Coming from investment banking into maritime, one of the biggest differences I noticed was how manual many workflows still are. In many cases, you have two companies talking to each other purely through email and PDF attachments. In other industries, you’d see two systems talking directly through APIs instead.

There’s nothing inherently wrong with email, but in maritime the complexity and nuances of operations have slowed digitalisation, and that has consequences.

The first big one is that subject matter experts spend a lot of time on admin. Highly experienced people who should be focused on risk, safety, and operations end up doing manual checks, chasing documents, and stitching information together. That makes it very hard to scale.

The second is data fragmentation. When everything lives in inboxes and PDFs, it’s incredibly difficult to aggregate and analyse even a year’s worth of information. You’d have to dig through emails and files and try to piece it together manually. It’s not impossible, but it’s hard and inefficient.

Digitalisation is improving fast — especially now with AI — but I still think maritime is two steps behind some other sectors. That gap is exactly where we want RightShip to play: connecting data, reducing manual work, and giving people better tools to manage risk.

Q: We hear a lot about RightShip’s Agentic AI. What does that mean in practice?

Marlon:

Agentic AI is what I call “phase two” of AI. Traditional AI answers questions. Agentic AI takes action.

We create specialised AI agents, each focused on a specific task, and embed them into workflows so they work alongside humans. They handle the repetitive work — reading documents, highlighting key lines, running calculations — and they help us maintain consistency across decisions.

Humans still make the final call, but AI acts as both decision support and action taker. It allows us to scale operations far beyond what manual processes could achieve.

Let me give you a few examples of where Agentic AI is already embedded in our products and how it actually helps people make better decisions, not just faster ones.

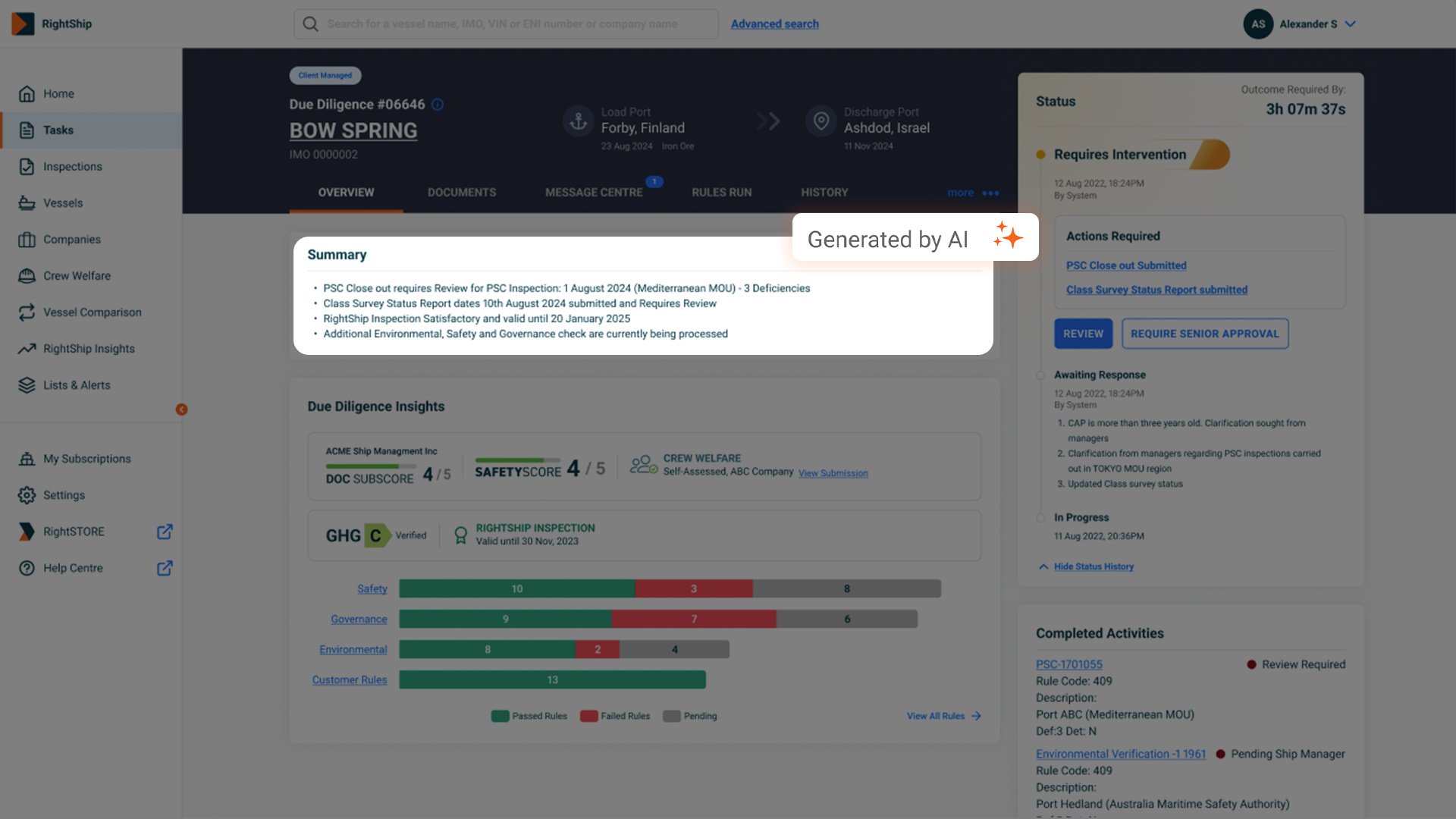

Due Diligence Hub

When you’re vetting a vessel, you’re often dealing with large, unstructured documents — class status reports, P&I documents, safety certificates — all with different formats, different layouts, sometimes different languages. Traditionally, someone would have to scroll through 40 or 50 pages just to find the 8 to 10 lines that matter.

AI now does that work automatically. It reads the document, understands the context, and highlights only the relevant sections. What that means in practice is clearer insights, presented upfront. The human doesn’t waste time searching; they spend time evaluating. So the “showing up” part isn’t just speed — it’s the fact that we surface the right information at the right moment, enabling much more confident and consistent vessel assessments.

So the “showing up” part isn’t just speed — it’s the fact that we surface the right information at the right moment, enabling much more confident and consistent vessel assessments.

Fleet Focus (Part of RightFLEET)

Fleet Focus takes a huge amount of data — PSC records, RightShip inspections, incidents, closeouts — and AI reads everything, connects the dots, and identifies themes.

If you want to understand all lifeboat-related issues across different data sources, you can do that instantly. More importantly, you can track whether those issues are getting better or worse over time. That’s where the insight comes in.

It’s not just data aggregation — it’s risk signal amplification. You see where patterns are emerging, where preventive action is working, and where additional attention is needed.

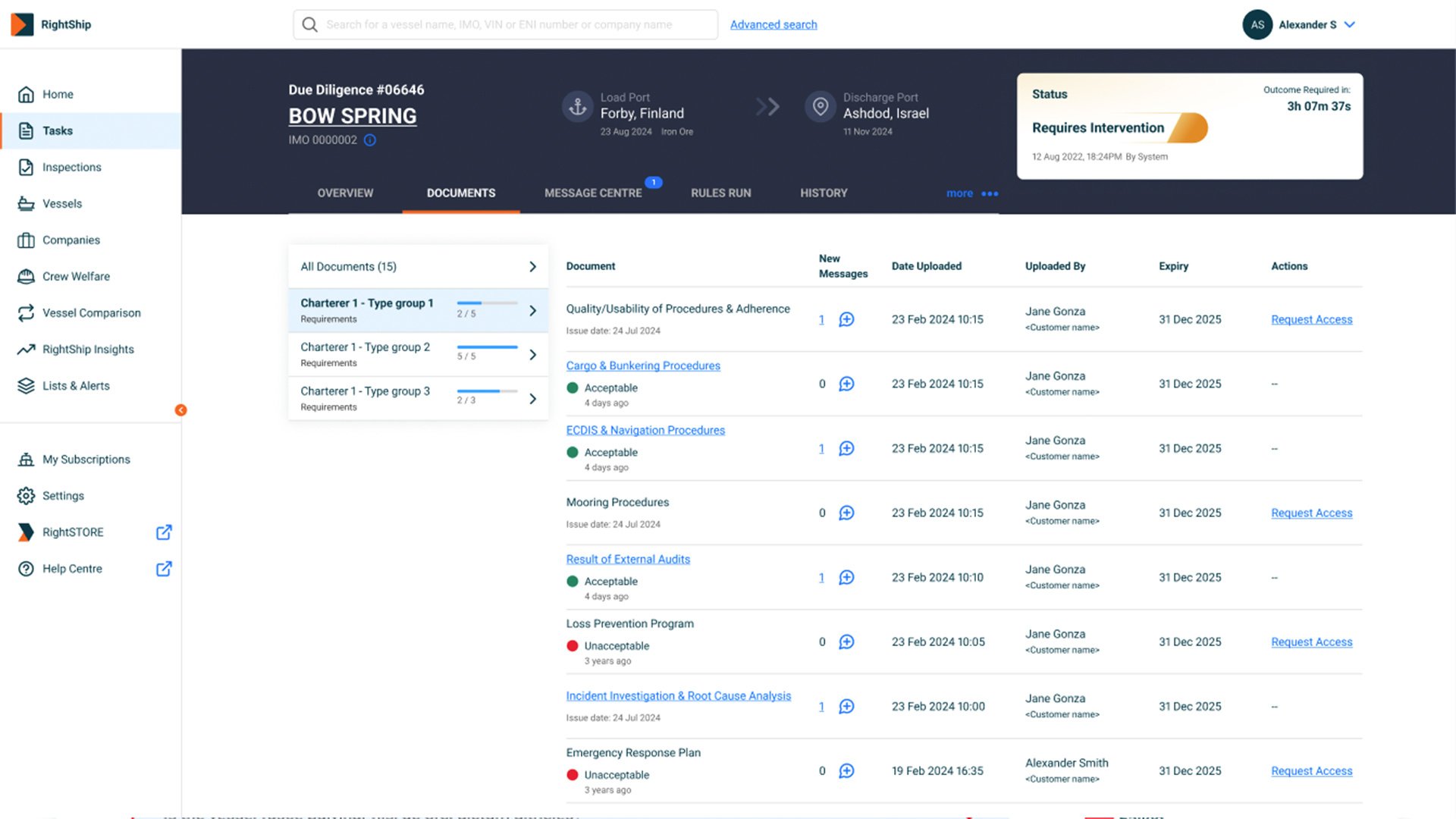

Document Management Centre

AI validates every uploaded document immediately — whether it’s the correct file, whether it’s current, whether it meets the requirement. That eliminates time wasted on incomplete submissions and reduces friction between charterers and managers.

Here, the insight is simple but powerful: you know exactly what’s correct, what’s missing, and what needs attention right now, without waiting for someone to manually check it.

Across all three products, the pattern is the same: AI does the heavy lifting, and the human gets the insight — fast, clear, and ready for decision-making.

Q: There are many AI products in the market today. What makes RightShip’s approach different?

Marlon:

That’s always a hard question because there are so many permutations out there. But what I think really differentiates us is that we use AI to amplify the output of the human, not replace it.

I work closely with our subject matter experts. These are people who’ve been at sea — they’ve experienced incidents, they’ve seen what happens when certain measures aren’t taken, or when there isn’t enough time to focus on safety. Their expertise is incredibly valuable.

I want them spending their time on work that adds real value, not on administrative tasks. So we apply AI wherever it can take over repetitive work — reading long documents, highlighting the relevant text, doing calculations — tasks that humans can do, but that are time-consuming and add little value.

AI today can parse unstructured data like PDFs with ease. It doesn’t matter what format or language it’s in; AI can extract and translate it. That lets us streamline workflows and ensure our experts are focused on the meaningful decisions that improve safety.

Q: How do you ensure your AI tools stay trustworthy, secure, and compliant?

Marlon:

It all starts with having a solid data foundation. In IT we say “garbage in, garbage out,” and that’s absolutely true for AI. Your data needs to be validated, fresh, and well governed. That’s why we’ve built a framework of well-governed data products — we start from the data before we even think about interfaces or features.

Then comes privacy by design. When an AI agent accesses data, it goes through the same checks and balances as a human user — authentication, authorisation, full data lineage. You can trace exactly what the AI touched and why.

And we always have safeguards. I use the analogy of car brakes: the brakes don’t exist to slow the car down; they exist so you can drive faster with confidence. Our AI guardrails work the same way.

Wherever human judgment is needed, we have a human-in-the-loop mechanism. The AI supports the work, but humans always govern the final output.

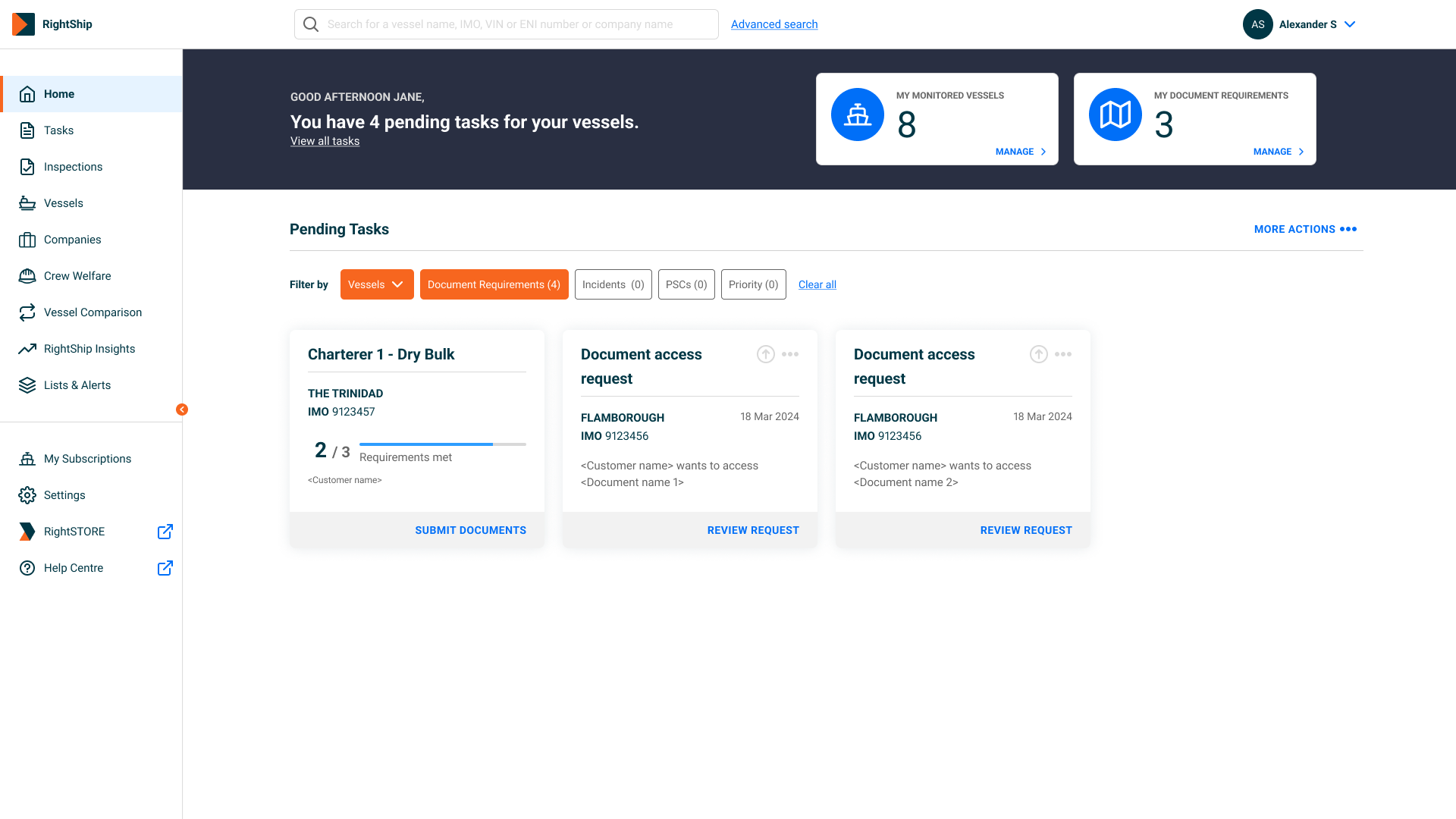

After talking about technology and AI, we transitioned into our solutions and how we turn those capabilities into practical tools.

Q: Who is the Due Diligence Hub for, and how is it changing the vetting process?

Marlon:

RightShip has been in the vetting business for 24 years; we’ve really mastered that service. But we realised not everyone vets through us — many companies have their own in-house vetting teams.

What we wanted to do was take the best of what we’ve built internally — our technology, our workflows, our access to data — and export that so those teams can vet with the same level of capability.

When we spoke to these in-house teams, their pain points were clear:

-

They rely on emails, attachments, and Excel files.

-

They often lack the data they need when making time-sensitive decisions.

-

Commercial teams are pushing for quick turnaround.

AI helps solve these problems. For example, if a ship manager sends the wrong file — which happens a lot across time zones — AI can identify it instantly and tell them why it’s wrong. That alone can save 24 hours.

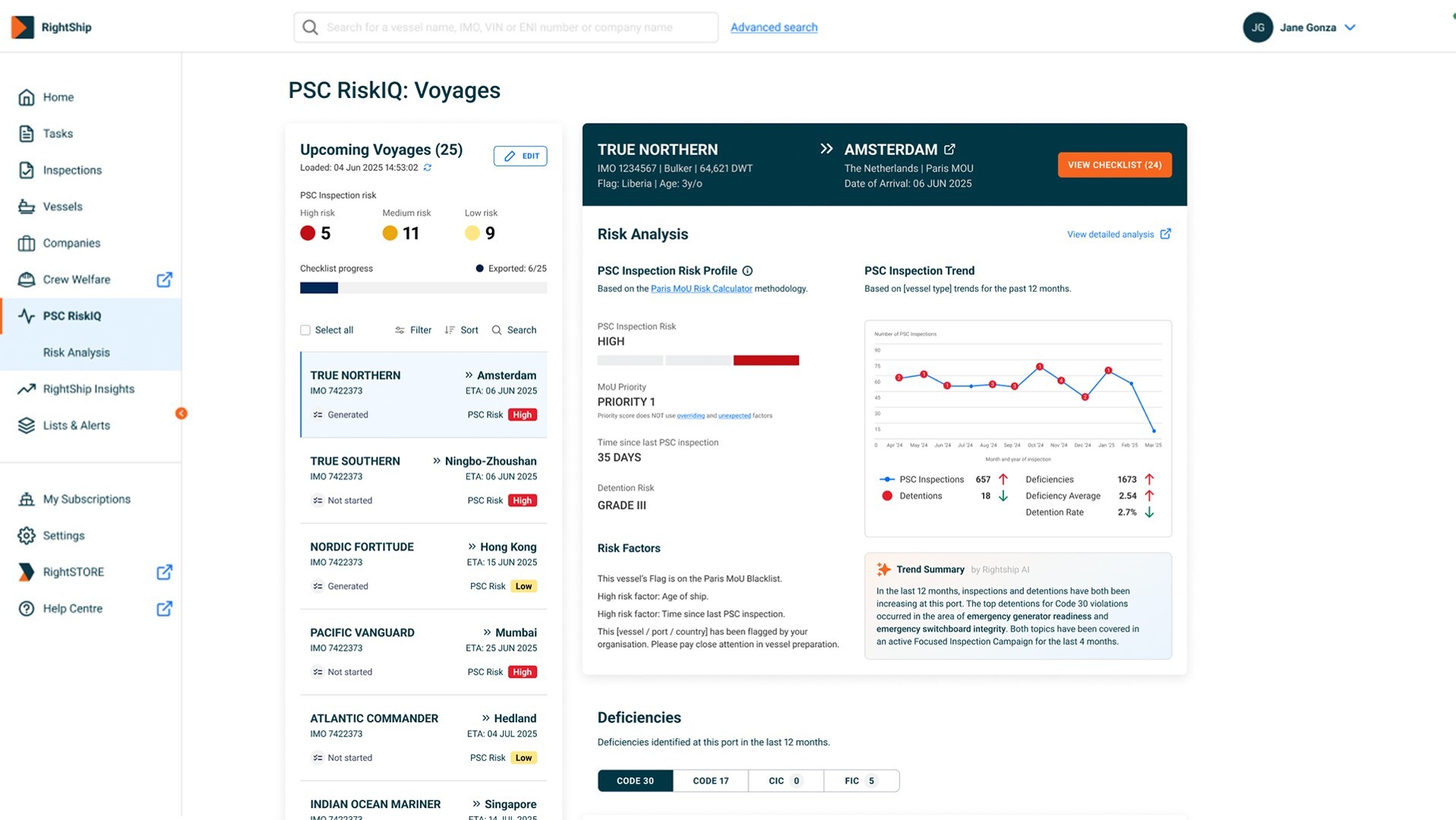

Q: RightFleet has evolved a lot. Why add tools like Fleet Focus and PSC RiskIQ?

Marlon:

Products are never static; they evolve. Historically, RightShip gave owners and managers access to data — safety score, GHG rating, vessel timelines — and left the decisions up to them. That was fine for the early days.

But through our product co-creation work, we learned more about the jobs to be done for owners and managers. For example, many of them spend huge amounts of time preparing their vessels for PSC inspections, trying to minimise deficiencies and avoid detentions.

We already had the data needed to help them. So the question was:

How do we make it easier for customers to use that data?

PSC RiskIQ and Fleet Focus aggregate, interpret, and surface insights automatically. Instead of owners manually piecing information together, the product does that work and presents insights directly. You’ll see more of these tools under the RightFleet subscription — tools that make our data faster to use and more valuable for day-to-day decision-making.

You’ll see more of these tools under the RightFleet subscription — tools that make our data faster to use and more valuable for day-to-day decision-making.

Q: Document Management Centre (DMC) feels like a major shift. What’s the vision behind it?

Marlon:

DMC started with one question: How do we make vetting faster?

When we looked at vetting closely, we realised that the waiting typically begins after someone requests a vet. That’s when the clock starts — and that’s when managers start gathering documents. But what if the documents were already there?

So the initial idea was simple:

Let managers upload documents proactively, so when a vet is requested, we can respond instantly.

But then we dug deeper:

Why are we even asking for this document? What exactly needs to be validated? Why are we sharing entire 60-page files when only two lines matter?

That’s where AI comes in. AI can validate documents as soon as they’re uploaded and eventually surface the exact lines that match a requirement.

This creates a much more streamlined experience for charterers — who can define their requirements — and for owners and managers — who can upload everything through one system. It’s becoming a bridge that improves transparency and reduces friction across the entire vetting workflow.

It’s becoming a bridge that improves transparency and reduces friction across the entire vetting workflow.

Q: Hybrid inspections are gaining momentum. How is RightShip approaching this?

Marlon:

One of the biggest pain points for inspections is that crews are already extremely busy. A 12-hour onboard inspection sounds like just a number, but imagine working a 12-hour shift when you’re already carrying a heavy workload. It has a real impact on crew welfare.

When we analysed the inspection workflow, we saw that a lot of that time was spent reviewing documents together onboard. So we asked: Why can’t that be done offline?

With DMC, ship managers can upload the required documents upfront. Our inspectors review and validate them before stepping on the vessel. We estimate this can save up to two hours of onboard inspection time.

And this is only the beginning. We’re already working on other areas that could be handled off-vessel. The direction is clear: shorten inspection time while maintaining quality, and allow inspectors to focus their onboard time on what truly matters.

Q: Looking ahead five years, what outcome would you love to see delivered through RightShip?

Marlon:

The maritime industry is incredibly complex. That’s why many processes stay manual and why risk assessment varies so much across charterers, ports, insurers, owners, and managers. It’s fragmented and time-consuming.

In five years, I want technology to help bridge that gap. I want risk assessment to be more transparent, more explainable, more consistent, and more cost-effective — something that just happens with every transaction, not something people struggle through.

We need to raise the bar for the industry without making everyone’s life harder. Technology is what will enable that shift.

Q: What motivates you personally to keep pushing innovation in this space?

Marlon:

I’ve always loved building products. Writing code, creating tools — that’s something I’ve been passionate about for years. But more than that, I love building things that genuinely make someone’s life better.

At RightShip, I get to pair that passion with a meaningful purpose. There’s a lot to do in maritime safety and sustainability, and I truly believe technology — when used the right way — will help us reach that vision faster.

That sense of purpose is what gets me up in the morning with energy.

RightShip Newsletter

Want to stay updated on future product updates, industry insights, and upcoming events?