RightShip hosted our second webinar in our Pilot Ladder Arrangements series which has received a huge response from the community.

You can download your own copy here.

We had the honour of having two esteemed pilots Captain Arie Palmers and Captain Adam Roberts join RightShip's own pilot Captain Christine Shank on our webinar and answer questions from the audience.

Pilot Ladder Webinar Part 2 Q+A

The official recommendation is to use pilot ladders for 30 months. Is this valid? What if a newly received ladder has a test certificate with an old date (for instance, one to two years old). In that case, shouldn't it be 30 months from the first use date?

Capt. Adam Roberts: 30 months came from ISO799-1:2019 requirement for the ladder to be tested by the original equipment manufacturer. There are numerous other pieces of equipment onboard that need to be replaced or serviced based on date of manufacture, i.e., life rafts, pyrotechnics, batteries, medicines, etc. This is why establishing a relationship with a reputable supplier/manufacturer is critical.

Capt. Arie Palmers: At the moment a strength test is mentioned after max 30 months. In the new regulations an expiry date will be specified at 30 months after manufacturing date. The manufacturing date has been chosen because it is the only date that you can check. Most ladders however do not survive to the age of 30 months due to bad storage, incorrect rigging, environmental exposure, etc.

How can the ship staff confirm whether the rope used is A-grade manila or not? Can we trust the certificate issued?

Capt. Adam Roberts: The ability to confirm A-grade manila comes from onboard training. Assurance comes from using a trusted and reputable manufacturer/supplier. In short, I would not trust certificate alone. There are many ladders sold with enormous markups that you can tell are fraudulently certified.

Capt. Arie Palmers: If the staff cannot confirm whether it is manila rope or not, they must be able to recognise the smell of manilla: it smells different to other types of rope. For European ports, a certificate can be checked on mared.org (EMSA). If a manufacturer is not listed there, you can be sure it is an “illegal ladder”.

As a crew, we often keep one spare pilot ladder onboard. Should we use it 30 months from the date of manufacturing or from the put-in-use date?

Capt. Adam Roberts: When certified to comply with ISO 799-1:2019 the ladder needs to be tested by the original equipment manufacturer at intervals of not more than 30 months. The manufacture date is the only verifiable date available to inspectors and surveyors. It should be borne in mind that 30 months is a maximum, and some ladders may need to be removed from service much earlier than that based on condition.

Capt. Arie Palmers: Date of manufacturing. Ladders are inexpensive, change them often!

Manropes are used for 12 months, but the ladders’ validity is 30-months at some Australian ports. Why is the validity different for these two items?

Capt. Adam Roberts: A recent incident occurred in Fremantle Western Australia in which both man ropes parted causing the pilot to fall some seven metres to the deck of the pilot cutter. During the investigation, it was determined that manropes, being more portable than pilot ladders, are often used for tasks other than pilot boarding. This was viewed as a possible contributing factor to them deteriorating faster than pilot ladders. 28-32mm manila being widely available with relative ease, the ports concerned adopted this policy.

Capt. Arie Palmers: Recently a terrible accident happened with manropes younger than 30 months, therefore now in Australia the max age is 12 months. Probably also happened due to bad storage/rigging, but that’s just my educated guess.

800 dollars for a new one? No, sir, we have been charged 2500 USD in EU ports. 800usd will get a ladder in China.

Capt. Adam Roberts: This figure is based on quote received from a reputable manufacturer on 13th September 2023. They quoted $1065 Singapore dollars($USD780) including local delivery.

Capt. Arie Palmers: If you are charged $2500, for a ladder of about 9m length, you have been ripped off by the ship chandler. Contact the manufacturer directly to get the correct price for your ladder.

RightShip: Price and/or availability should not be the only deciding factors when choosing a pilot ladder provider. It is all about due diligence.

At Australian ports, a pilot ladder costs USD 1500 at least, not USD 800.

Capt. Adam Roberts: This figure is based on quote received from a reputable ladder manufacturer on 13th September 2023. They quoted $1065 Singapore dollars($USD780) including local delivery.

For comparison a cancellation for a two or three tug ship due to non-compliant ladder in East Coast Australia ports will be in the order of $30,000-$50,000 USD.

The fines issued to Master and operating company of AAL Dampier when both manropes parted and the pilot fell seven metres was approx. $USD24,000 which the judge commented “The maximum penalties in relation to these offences are fines. I might make the observation the fines do seem to be a bit out of currency, in my view, compared to other fines for similar matters that come before the courts, but the maximum fines for the breach of the Marine Order regulations is $11,100 in the case of an individual and five times that in the case of the company.”

Of course, this does not reflect the cost of lawyers, personal cost to the master (he was fired), delays, and reputational damage. At $1500 or $800, it is still much cheaper to adopt a policy of regular scheduled replacement than risk the alternative.

Capt. Arie Palmers: If you are charged 2500 for a ladder of about 9m length, you have been ripped off by the ship chandler. Contact the manufacturer directly to get the correct price for your ladder.

Are replacement steps acceptable for repair?

Capt. Adam Roberts: Steps must be replaced with steps supplied by original equipment manufacturer.

Capt. Arie Palmers: Yes, two max and to be replaced by original ones at first opportunity. A genuine manufacturer will supply official and certified replacement steps. Please no DIY.

RightShip: Please refer to IMO Res. A. 1045 (27): 2.1.3 “No pilot ladder should have more than two replacement steps which are secured in position by a method different from that used in the original construction of the ladder...”

We recently were asked by an agent to accept an unused coil. Date of test/manufacture 2003!

Capt. Adam Roberts: I hope you said no thank you!

Capt. Arie Palmers: Reject!! You have no idea how the coil has been stored the past 20 years. For example, if it had been stored close to some acidic products, the strength is gone.

RightShip: A ladder is only as strong as its weakest part.

What are the current regimes for pilots to report the non-compliant ladders?

Capt. Adam Roberts: In Australia pilots have easy access to systems to report to Port State Control. We are very fortunate to have an active regulator a Port State Control regime that takes safety seriously. My personal experience has been that when I report non-compliant arrangements it is followed up by an AMSA inspection. On the occasions I have refused to board vessels with non-compliant arrangements I have been supported by my employer.

Capt. Arie Palmers: In some countries pilots are obliged to report and some other countries don’t have these rules. IMPA strongly recommends rejecting and reporting every non-compliant ladder. Should indeed every non-compliant setup be rejected and the ship sent back to the anchorage, the entire problem would be solved before the end of the week.

RightShip: We are calling upon pilot associations, terminals, and port authorities to provide their feedback and suggestions to flag states, representatives in IMO, industry bodies and other stakeholders. This is the only way we can influence any future change.

Are manropes also manila ropes always?

Capt. Adam Roberts: Yes. Other types don’t provide sufficient friction when in use. The heat generated using synthetic fibres make them hard to hang on to. In wet conditions synthetic fibres can be very slippery.

Capt. Arie Palmers: Yes.

RightShip: Please refer to ISO 799-3:2022 Ships and marine technology – Pilot ladders – Part 3: Attachments and associated equipment.

We struggle to keep our spare pilot ladder due to the 30-month validity requirement; any suggestions about managing the spare ladder?

Capt. Adam Roberts: All I can suggest is, knowing this, adopt a conservative approach to replacement of in-service ladders, i.e., remove them from service at the first signs of deterioration or damage, replacing them with the spare. In the entirety of the cost of operating a ship, frequent replacement of pilot ladders and small ropes is a small expense. Really it is a mindset change that industry needs to accept these things like many others are a consumable item.

Capt. Arie Palmers: Replace them often…

When you say, “Don't look only at the certification but also look for a reputable supplier” You are challenging the whole certification system, can you elaborate on what the IMO is doing to ensure sub-quality products do not get certified?

Capt. Adam Roberts: I am not in a position to speak for the IMO. SOLAS V/23 is under review right now. IMPA, AMPI, and many other pilot associations will continue to advocate for higher standards that support both pilots and seafarers.

The photos I showed during the presentation demonstrate the multiple issues caused by accepting certification alone. This is not unusual in our industry. Many shipping companies don’t accept STCW certificates at face value and have screening processes for officers serving on their ships and in some cases won’t allow you to stand watch on the bridge of their vessels without completing more training. Ships are vetted all the time despite having all the necessary certification in place.

Capt. Arie Palmers: Sub-quality products, not only ladders, do get some certification, there is a lot to win. Check every item when delivered on board BEFORE you accept it.

RightShip: MED stands for Marine Equipment Directive 2014/90/EU. This is typically seen on the manufacturer’s name plate on the pilot ladder as well as the Certificate of Declaration of Conformity. This declaration is issued with certain information including:

-

Type approval requirement

-

Carriage and performance requirements

-

Testing standards

-

Type examination certificate no. (and the issuer which is typically an IACS member)

-

Quality system certificate no. (and the issuer which is typically an IACS member)

How many broken steps are allowed to be repaired?

Capt. Adam Roberts: Two steps for a SOLAS certified ladder. Refer to IMO RES A 1045/27 2.1.3

Capt. Arie Palmers: Two

RightShip: ISO 799-1:2019: 10.1 “...a ladder shall not include more than two replacement steps and one replacement spreader step.”

ISO 799-1:2019: 10.2 “If a ladder requires a third replacement step or a second replacement spreader step, it shall be rebuilt...”

Is there any suggested sample form for PMS of the pilot ladder? Rigging manropes with a combination ladder?

Capt. Adam Roberts: ISO 799-2:2021 provides requirements and recommendations for the maintenance, use, storage, and inspection of pilot ladders. Some manufacturers supply instruction and use manuals based on this standard. These could be used as a base for creating forms for PMS.

Capt. Arie Palmers: In ISO 799 there are example checklists for ladders.

What is the requirement for the rope to secure the pilot on the main deck? What is the required diameter and strength?

Capt. Adam Roberts: IMPA is currently conducting a further study into this area. The pilot ladder manufacturer should provide advice in the first instance. It is important the rope be:

-

1. Tagged, identified, and used only for the purpose of securing pilot ladders.

-

2. Regularly inspected.

-

3. Be of at least 50 Kilonewton breaking strain.

-

4. Be of a diameter that allows the crew to tie a tight rolling hitch between the steps of the ladder.

ISO 799-3:2022 5.3 When a pilot ladder is rigged at less than full length to accommodate changes in freeboard, the ladder shall be secured on both side ropes in the manner specified by the pilot ladder manufacturer. In the case of a rolling hitch, the rope shall be at least as strong as the side ropes and shall be secured to a deck securing strongpoint observing the following.

-

Any securing ropes used for such purpose shall be tagged and inspected in accordance with ISO 799-2:2021

-

Securing rope construction type, size and knot type shall be specified by the manufacturer and provided to the user in the instructions supplied by the manufacturer as required by ISO 799-2.

-

A ladder manufacturer shall provide advice to users on other approved methods of securing the ladder at less than full length. Manufacturers shall provide test data used to determine approved securing methods to the maritime safety administration for approval during the pilot ladder certification process.

Capt. Arie Palmers: Rope to be as strong as the side ropes. Diameter of rope depends on the type of rope.

RightShip: Please refer to ISO 799-3:2022.

If vessels don't receive a new pilot ladder certificate, what will be the solution? Will the nameplate on the ladder suffice?

Capt. Adam Roberts: Reject the ladder.

Capt. Arie Palmers: Every ladder must come with a valid certificate, if not you might have a cheap fraudulent ladder. The tag alone is not sufficient.

RightShip: Do not use until valid certificate is supplied by manufacturer.

Military vessels? We recently had a military exercise, and the standard of transfer arrangements was poor. We have been clear that they must follow merchant standards moving forward.

Capt. Arie Palmers: NATO vessels must comply with ANEP-77(naval ship code) which basically is a copy of the SOLAS requirements in case of ladders. It is not compulsory for naval ships to have a pilot on board. If the arrangement is poor, just say no and wait until it is rectified. You cannot be asked to risk your life because any vessel is not rigging a correct arrangement, too many people die every year due to this.

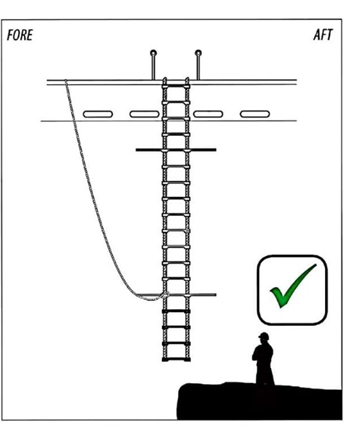

The retrieval line is not recommended to be rigged aft but fwd. - please share a sample phototo share with our crew. we saw this done wrongly sometimes. A few pictures of best practises will help.

Capt. Arie Palmers:

RightShip:

Please note that the views and opinions expressed in this Q&A document by the guest speakers are theirs and do not necessarily reflect the views or positions of RightShip LLC.