Q: What are the key updates in the latest RightShip crew welfare self-assessment?

The latest updates to the crew welfare self-assessment tool include:

- Question Level Explainers: To give users better clarity on what each question is asking for, question-level explainers have been developed. These are designed to help users of varying expertise levels understand and complete the self-assessment more effectively.

- Simplified Self-Assessment Process: The entire self-assessment journey has been made more intuitive and less time-consuming, with the goal of encouraging broader participation.

- Improved User Interface: The tool now boasts a more engaging and user-friendly interface to foster positive user engagement.

- Additional Features: New functionalities, including chapter and section progress indicators, auto-save, internal notes, enhanced validation and error messaging and form management board have been introduced to improve the experience.

Q: Why were these updates made to the crew welfare self-assessment?

A: Updates were made to address feedback and identified deficiencies in the original tool, including concerns about complexity and length of self-assessment, insufficient support and guidance and data privacy concerns. The aim is to position the tool as essential for operational excellence and maritime industry leadership, transcending basic compliance to enhance crew welfare and competitive advantage.

CHARTERERS/CARGO OWNERS

Q: Why should we adopt the Code of Conduct – Delivering on Seafarers’ Rights?

A: As a charterer/cargo owner, by adopting the Code of Conduct, you commit to transparency by establishing targets to shift your charters to shipowners/operators who meet the Code of Conduct, publicly reporting on this progress and working actively with shipowners/operators to support implementation of the Code of Conduct.

Adoption of the Code of Conduct shows that as a charterer/cargo owner you want to strengthen the due diligence process for informing your decision-making and the Crew Welfare platform can be used to support this.

Q: How do we use the Crew Welfare platform?

A: The full content of the Self-Assessment submissions will not be visible to external parties. Instead, a Self-Assessment completion badge will be available on each vessel and company page in the RightShip Platform.

SHIPOWNERS

Commitment and Benefits

Q: Why should we adopt the Code of Conduct – Delivering on Seafarers’ Rights and submit a self-assessment?

A: Adoption of the Code of Conduct shows that as a shipowner/operator, you understand the extent to which current operations meet crew welfare responsibilities. The Code of Conduct is based on international labour and human rights standards and principles, and the 52 clauses build on and go beyond the ILO Maritime Labour Convention (MLC), focussing on the full spectrum of seafarers’ rights and wellbeing.

The Crew Welfare self-assessment expands on the Code of Conduct and is open to any shipowner regardless of where they may be on their journey to improved policies and practices.

Self-Assessment Process

Q: Do we need to record a “Yes” or check all boxes in positive response in the questionnaire to achieve a pass?

A: Improving crew welfare is a journey and showing demonstrable progress is key.

We don’t expect you to tick every box. Please select all answers that apply to you. By completing the self-assessment, you obtain a clear indication on where you’re positioned today based on your results. This will help you to understand what actions you need to take to improve and meet the expectations laid out in the Code of Conduct. Completing the self-assessment year-on-year enables you to measure your progress over time and plan where to focus your budgets and resources.

Q: Do I need to be an existing RightShip user to self-assess?

A: Yes, hosted by RightShip, the self-assessment tool on the Crew Welfare platform is free for anyone listed as a DOC holder to fill in. To use the tool, DOC holders are required to create an account with RightShip, a process that is straightforward and simple.

DOC holders can download their completed self-assessment to share with clients and other interested stakeholders.

Anonymised, aggregated data will be used for progress reporting. However, the individual answers to a company’s self-assessments will not be made public.

Q: Can I sign up without having to submit a self-assessment?

A: Yes, adopting the Code of Conduct and using the self-assessment tool will help you understand the extent to which current operations meet crew welfare responsibilities. If you do not wish to submit data on the Crew Welfare platform, it is possible to download a PDF of both Code of Conduct and self-assessment tool.

It is suggested that you complete the self-assessment annually, and we recommend developing a crew welfare roadmap to improve, so that you have clear goals to measure against one year later.

Q: What are the obligations once we’ve completed the self-assessment?

A: Once you have submitted your self-assessment on the Crew Welfare platform, we encourage you to work with your teams to explore the areas in which you can improve and use your results as a guide to strengthen crew welfare where gaps are found. Given that we suggest you complete the self-assessment annually, we recommend developing a crew welfare roadmap to improve, so that you have clear goals to measure against one year later.

Q What does it require from us in terms of performance? Are there any metrics, standards, mandatory achievements required?

A: This is not a ratings-based self-assessment, you are not ranked against other operators. It is up to you to establish your level of commitment and build further from where you stand. However, we expect to see increasing industry interest in crew welfare regulation in the coming years and believe those who have made early and positive strides in the protection of their crews will be viewed favourably by the industry. That said, it is also an important ethical business practice.

Q: We’re already committed to crew welfare – why should we complete the self-assessment?

A: The self-assessment provides you with an indicator of your progress and a tangible document that you can share with your organisation or external stakeholders, raising awareness of crew welfare efforts and increasing transparency. Whether an existing RightShip user or not, you will receive a download of your self-assessment following completion of the questionnaire.

This enables you to clearly display your commitment to crew welfare. Many charterers are actively seeking owners and operators who can show their crew welfare during the due diligence process, so the self-assessment helps to highlight your efforts.

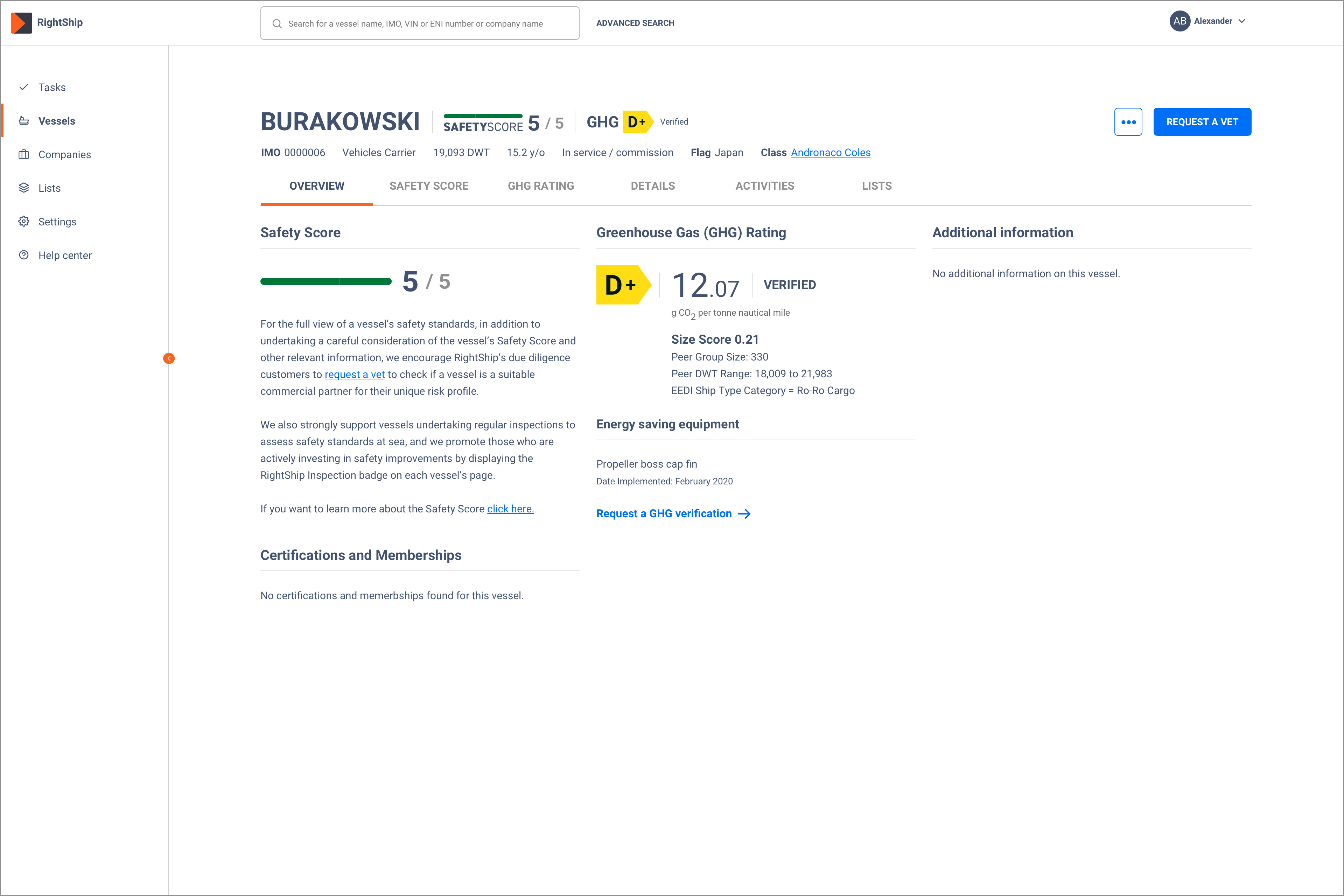

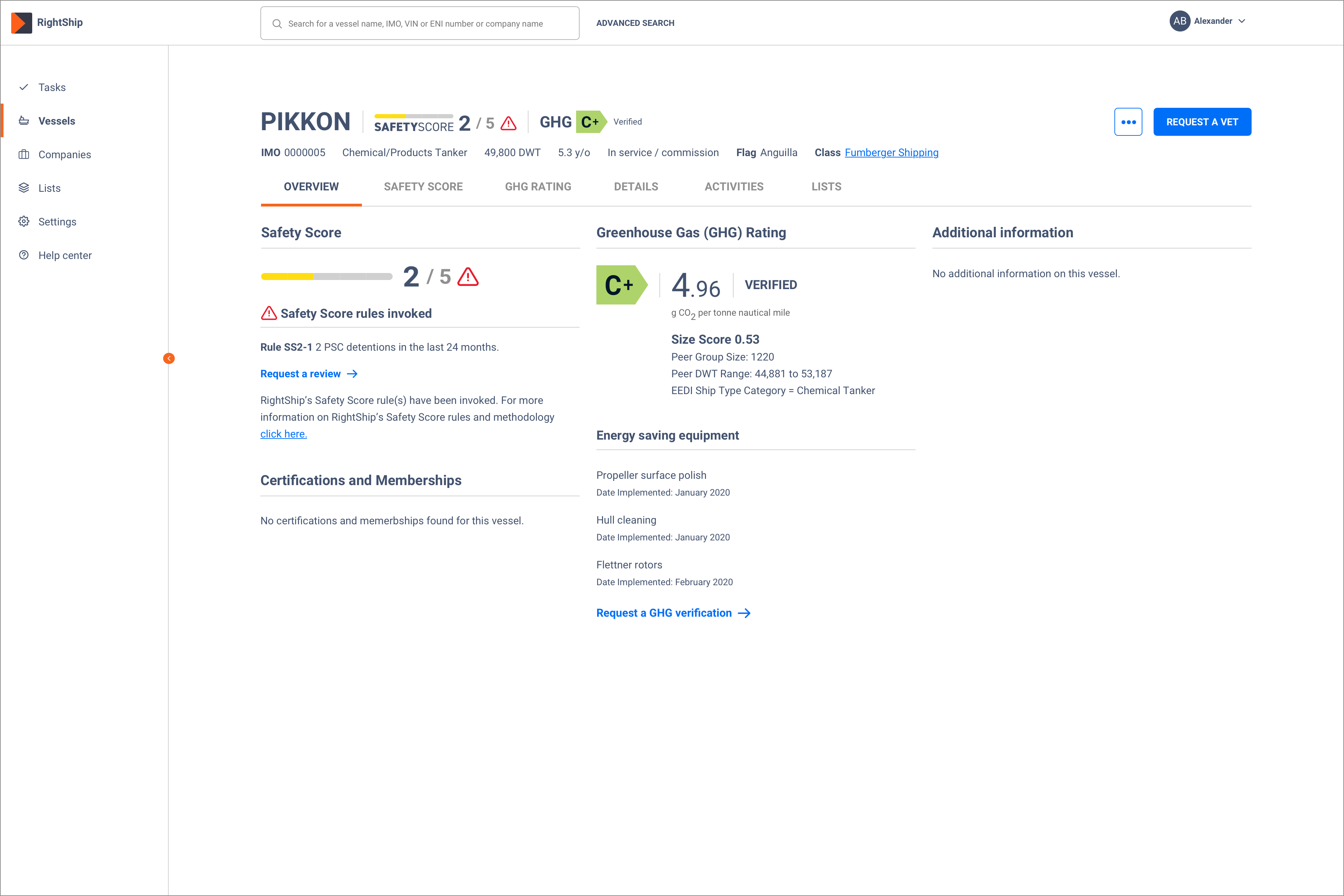

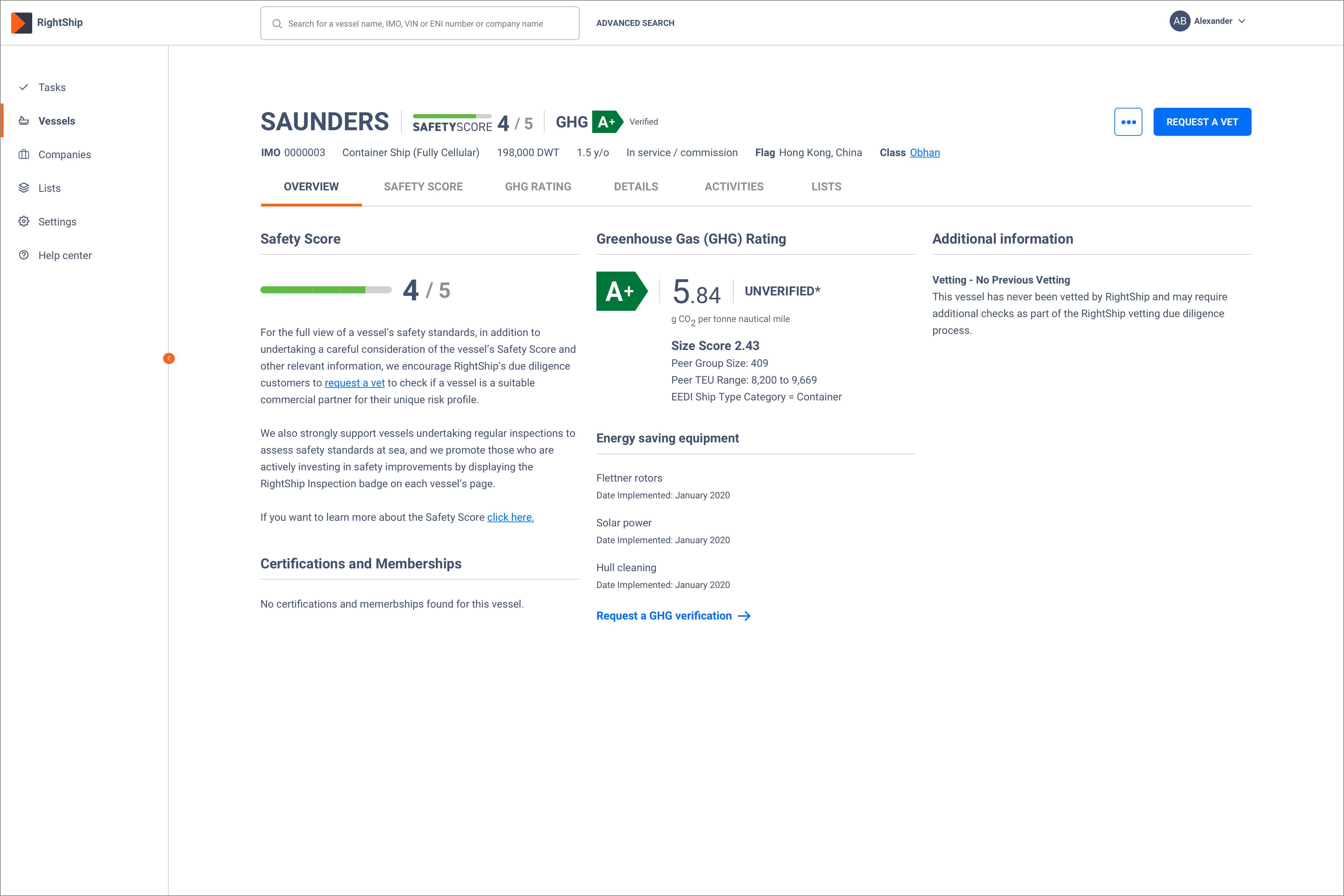

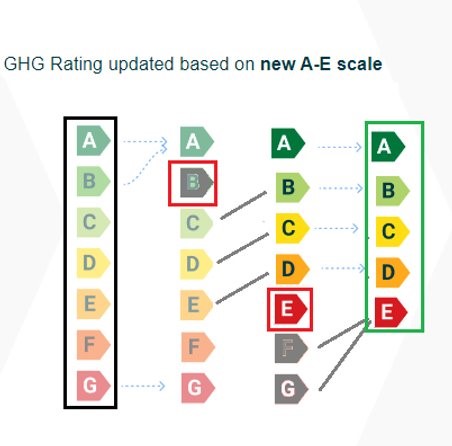

Q How is the data housed?

A: The full content of the self-assessment submissions will not be visible to external parties. After completing the self-assessment, you will be provided a PDF of your responses via an email from RightShip. Your results will be stored in the Crew Welfare platform, but the full content of the results nor data will be visible to third parties. On completion, a Crew Welfare badge will appear on the company’s vessel page within the RightShip Platform. Ship owners and managers will be sent a pdf summary of your submission to share with clients and other interested stakeholders. You will also be able to see the status badge for other participating owners and operators. Data entered is unverified and does not affect your RightShip Safety Score, GHG Rating, Dry Bulk Inspection or Vessel Vetting outcomes.

Submitted data will be used in an anonymised, aggregated capacity to measure progress and may be included in a progress report. You will be prompted annually via email to update your data or ensure it is still accurate.

Q: Is the disclosed data reviewed, vetted, rated and/or filtered?

A: The submitted data is not reviewed nor verified and will not affect your RightShip Safety Score, GHG Rating, Vessel Vetting process or your Dry Bulk Inspection outcomes. Anonymised, aggregated data will be used for industry wide progress reporting.

Q: How much does it cost?

A: The self-assessment tool and the Crew Welfare platform are free to use and helps support the industry improve crew welfare.

Updates and Editing the Self-Assessment

Continuous Improvement and Editing

Q: Can I edit my self-assessment after I've submitted it?

A: Yes, you can edit your self-assessment at any time after submission. We encourage you to update your assessment as your practices evolve or when you implement new measures to improve crew welfare. This flexibility ensures that your self-assessment accurately reflects your current practices and efforts in real-time, rather than waiting for the annual renewal period.

Q: Why is it encouraged to edit my self-assessment before it expires?

A: Editing your self-assessment as you make improvements or changes in your crew welfare practices allows for a dynamic and up-to-date reflection of your commitment to seafarers' wellbeing. This approach supports continuous improvement and allows you to promptly document and share advancements in crew welfare with stakeholders. It also demonstrates your proactive stance in maintaining high crew welfare standards, reinforcing your company's dedication to ethical and responsible operations.

Q: How can I edit my self-assessment, and are there any limitations to the number of edits I can make?

A: Editing your self-assessment is straightforward and can be done at any time to reflect the latest changes in your crew welfare practices. Simply log into the RightShip platform and select 'Crew Welfare' from the left menu. You will then be directed to your form management board, where you can choose the assessment, you wish to edit. We recognise that continuous improvement is a key part of crew welfare. Therefore, there are no restrictions on the number of edits you can make. This allows you to update your assessment as often as needed to accurately represent your current practices and initiatives in crew welfare. Whether it's minor adjustments or significant changes to your operations, the platform supports your ongoing efforts to enhance seafarer welfare.

Q: What happens after I edit my self-assessment? Is there a review process?

A: After editing your self-assessment, the updated information is saved and reflected immediately. There is no formal review process by RightShip for these edits, as the self-assessment is designed to be a self-reported tool. However, we recommend ensuring that any changes or updates you make are accurate and verifiable, as this information may be of interest to charterers, regulatory bodies, and other stakeholders who value transparency and commitment to crew welfare.

For Users with Current and Expired Assessments

Valid and Expired Assessments

Q: What does the update mean for users with a currently valid self-assessment?

A: Your current self-assessment remains valid until its expiration date, and we acknowledge the effort and commitment you have demonstrated towards maintaining high crew welfare standards. We encourage you to explore the enhanced self-assessment tool, which offers improved functionalities, a streamlined process, and additional support to better reflect and improve upon your crew welfare practices. Transitioning to the enhanced self-assessment tool when ready will enable you to benefit from these improvements and continue demonstrating your commitment to crew welfare.

Q: My self-assessment has expired. Can I renew it using the previous version of the self-assessment?

A: If your self-assessment has expired, renewals using the previous version of the self-assessment are not possible due to the introduction of the updated questionnaire, which includes different questions and a more user-friendly interface. You will need to start afresh with the enhanced self-assessment questionnaire. This approach ensures that your crew welfare practices are assessed against the most current standards and expectations, providing a more accurate reflection of your commitment to seafarer welfare. Starting afresh with the enhanced self-assessment tool also allows you to take full advantage of the new features and support designed to facilitate a comprehensive assessment of your crew welfare initiatives.

Q: How does the enhanced self-assessment tool differ from the previous version, and why should I complete it if my previous assessment has expired?

A: The enhanced self-assessment tool offers several key improvements, including question-level explainers for better clarity, a simplified assessment process to encourage broader participation, enhanced data privacy measures, an improved user interface, and additional features such as chapter progress indicators and auto-save functionality. These updates are designed to make the self-assessment process more intuitive, user-friendly, and effective in capturing your crew welfare practices. Completing the enhanced self-assessment ensures that your assessment reflects the latest standards and best practices in crew welfare, reinforcing your company's commitment to the wellbeing of your seafarers.

Submission Requirements Changes

Simplifying the Process

Q: Why is the submission of supporting documents and comments no longer mandatory in the self-assessment?

A: We have updated the crew welfare self-assessment process to make it more user-friendly and efficient. Recognising the importance of a streamlined approach for our users, we've removed the mandatory requirement to submit supporting documents and comments with each assessment.

This change aims to:

- Reduce Complexity: Simplifying the self-assessment process enables users to complete it more quickly and with less administrative burden.

- Enhance User Experience: By removing these requirements, we focus on the essential aspects of assessing crew welfare practices, making the process more accessible to a wider range of users.

- Encourage Broader Participation: By minimising the time and effort needed to complete the assessment, we aim to encourage more companies to participate, contributing to a broader understanding of crew welfare standards across the industry.

Future Directions

Looking Ahead: The Next Phase of Crew Welfare Assessment

Q: What future enhancements are planned for the crew welfare self-assessment tool?

A: Future enhancements planned for the crew welfare self-Assessment tool include:

- Collaboration Feature: An upcoming addition that will allow users to invite colleagues to collaborate on the self-assessment tool together. This feature aims to streamline the assessment process by enabling teamwork and ensuring that all relevant inputs are considered.

- Scoring System: There is consideration being given to the introduction of a scoring system for the self-assessment. This system would enable companies to receive a score upon completion of the self-assessment, allowing them to benchmark their performance against industry standards and gain insights into where they stand in terms of crew welfare practices.

Showcase your commitment to seafarers by completing the

Showcase your commitment to seafarers by completing the