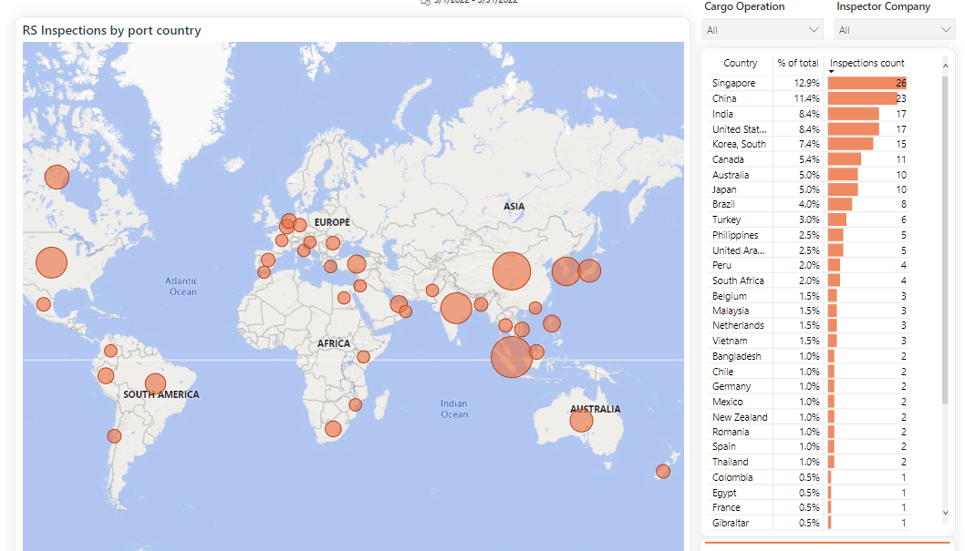

In May of 2022, RightShip inspections were still in high demand, with the majority being conducted in the Far East. As a result of China's restrictions on inspections, Singapore, India, the United States, South Korea and Australia have witnessed increased activity. Despite the restrictions in China, this location remains the most active for inspections, although it may mean inspectors need to quarantine for a period of seven to 28 days and arrive at ports three to four days in advance to undergo COVID tests prior to boarding and inspection.

Operation status - RightShip inspection:

Ideally, inspections should be conducted at discharge ports or anchorages, although other operational statuses can be considered. Performing RightShip inspections while the ship is in dry dock is not something we recommend to any ship's operator; we accept inspection applications in dry dock to support the commercial requirements of the vessel. However, the ship's operator should be aware that the number of findings will be higher when the ship is under repair, compared to when the ship is in service and out of dry dock.

Plan for RightShip inspection:

Numerous impediments, such as weather, local government restrictions, and the inspector's availability could impede the planning of the ship's inspection. A proactive vessel operator will not delay the inspection to the last minute and will use the RightShip Inspection Ship Questionnaire (RISQ) to ensure the vessel is ready in all respects. It is also crucial to prepare ahead and discuss the vessel's forward itinerary with the RightShip Inspections team, so that they can investigate all available options open to you. You can contact the RightShip team at dryinspections@rightship.com or obtain additional information here.

Responding to an inspector’s findings:

Root cause analysis (RCA) is the process of discovering the underlying reasons of a problem to establish the best solutions. An effective root cause analysis is one that methodically addresses fundamental issues, as opposed to merely managing symptoms and correcting the immediate cause of the fault.

The vessel management should submit a meaningful root-cause analysis, including corrective actions and sustainable long-term preventative actions, for each nonconformity. This should consist of:

- Description of the finding

- Photographs

- Immediate causes

- Root cause

- Corrective/Preventive actions

Failure to address root causes and identify effective preventative actions and failure to adopt good practices that lead to an improvement in the safe operation of the vessel can negatively affect the inspection result, with a consequential reduction in the validity period assigned to the inspection.

.png.webp)